Case Study:

Conversion of bags to pleated bags solved capacity problem at gypsum board production

Location:

- CROATIA

Operation:

Production of gypsum board

Dust type:

Gypsum, paper

Problem:

- Holes in bags

- High emission. Customer wants <10mg

- High dP - up to 22mbar. Customer wants 12-15mbar

- Lifetime max 1 year

Solution:

- Multifit pleated filter bags from Nordic Air Filtration were installed

TECHNICAL FACTS |

||

| BEFORE | AFTER | |

| Bag filter | Pleated bag Solution | |

| Dusttype | Gypsum, paper | |

| Collector type + running hours/year | Intensiv 5000 hours pr year | |

| Airflow m3/h | 18.500 | |

| Filter model | Conventional filter bag | Multifit pleated bags |

| Media/cloth type | PES Needlefelt | Polyester media with PTFE coating |

| Length mm | 4.000 | 2.000 |

| Number of bags/pleated bags | 80 | 80 |

| m² in each bag/pleated bag | 2 | 4,3 |

| m² in unit | 160 | 344 |

| Air-to-cloth ratio m3/m2/h | 116 | 54 |

Advantages:

- By installing pleated filter technology with more filter media area in the existing baghouse, the air-to-cloth ratio was lowered

- The shorter filters (4.000 vs. 2.000 mm) improves pre-separation of heavier dust particles in the hopper - before the particles reaches the filter media. This, with the lower air-to-cloth ratio and spun bond media charateristics, is a big part of why the filter life is prolonged

- Same pulsing equipment could be used with the pleated bags

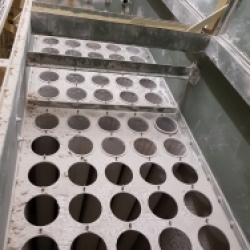

Before:

Solution after:

Sales Representative:

MG