Case Study:

Location:

- SLOVENIA

Operation:

Dust type:

Problem:

Sugar dust combined with air poses a risk of explosion if the equipment doesn't comply with ATEX regulation.

End-user being a sugar processing group, wished a filter design made to insuring a secure working environment in a dust explosive atmosphere.

Furthermore, the requirements are to meet EC1935:2004 standards, that comply to the food processing industry.

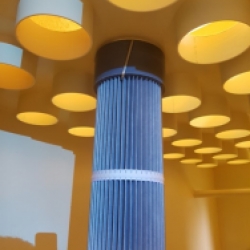

In 2020 64 Pleated Bags with antistatic proporties; both 900ALU filter media and antistatic cable, were installed in a new dust collector for ground sugar transport and silo dedusting.

For securing a low dust accumulation at the filter bottom, the Star Bottom filter design was chosen.

Electrical conductivity measurements were made on each Pleated Bag and proven superb. The highest measured value was 67,4Ω - a very low value representing an excellent result. Conductive materials and materials with a discharge capacity have to be earthed safely in order to ensure the discharge process. However, the resistance to earth shall not exceed 10⁶ Ω.

TECHNICAL FACTS |

|

| Pleated bag solution | |

| Airflow in unit | 8000 m³/hour |

| Dusttype | Crystal sugar dust |

| Collector running hours/year | New |

| Filter model | FBLPBG Star bottom Bottom Loader |

| Media/cloth type | Pleated Antistatic Polyester with PTFE membrane |

| Dust load | 3g/m² |

| Number of bags/cartridges | 64 |

| M² in each bag/cartridge | 2,5 |

| M² in unit | 160 |

| Air-to-cloth ratio (m³/m2/h) | 50 |

| Bag house type | LIVING |

Advantages:

- Explosion-proof filter design ATEX certified

- Excellent electrical conductivity properties

- Emissions below 3mg/m³

- EC1935:2004 certified equipment to be used in food & beverage industry

Solution after: